Checking out the Adaptability and Applications of Metal Casting in Modern Sector

Metal Casting are important to numerous markets, demonstrating their flexibility in applications ranging from auto components to aerospace design. Different casting procedures allow for the creation of long lasting components and intricate designs. As industries progress, developments and lasting methods are reshaping the landscape of Metal Casting. This improvement increases crucial questions regarding the future role of Metal Casting in manufacturing and style performance. What growths might redefine sector standards?

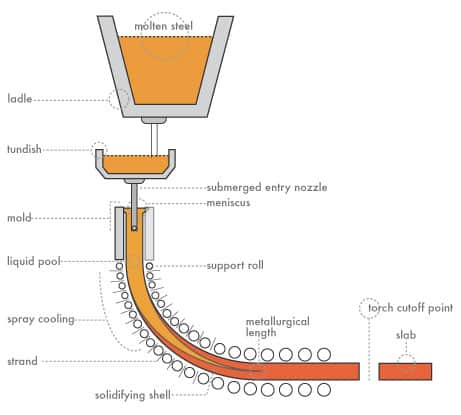

Summary of Metal Casting Procedures

Although Metal Casting has actually developed significantly for many years, its basic procedures continue to be crucial in contemporary manufacturing. Metal Casting entails several crucial techniques, including sand spreading, investment casting, and pass away spreading, each customized to details applications and products. Sand casting, one of the oldest techniques, uses sand molds to shape liquified steel, making it perfect for large components. Investment casting, recognized for its accuracy, employs wax patterns covered with ceramic to accomplish complex styles, typically utilized in aerospace and medical sectors. Die spreading, defined by high pressure, enables the fast manufacturing of intricate shapes with superb surface finishes, usually made use of for vehicle elements. Each process provides distinct advantages pertaining to product, cost, and intricacy compatibility, enabling suppliers to choose the most suitable technique for their needs. Therefore, understanding these procedures is necessary for optimizing production performance and accomplishing desired product specifications in a competitive market.

Key Industries Utilizing Metal Casting

Metal Casting play an essential duty in different crucial sectors, driving development and effectiveness. The vehicle market is among the largest consumers of Metal Casting, using them for engine elements, transmission housings, and structural components. In aerospace, precision spreadings are critical for airplane engines and architectural elements, guaranteeing safety and efficiency. The energy industry also greatly counts on Metal Casting for turbine parts in power generation, in addition to for oil and gas applications where resilience is paramount. In addition, the construction sector utilizes Metal Casting for structural frameworks, installations, and ornamental components. Production devices and equipment take advantage of spreadings, which offer robust and dependable components necessary for operation. Eventually, the clinical area makes use of specialized spreadings for medical tools and implants, showcasing the flexibility of Metal Casting across diverse applications. Each of these markets demonstrates the relevance of Metal Casting in progressing innovation and meeting particular practical requirements.

Benefits of Metal Casting in Production

The benefits of Metal Casting in production are countless, adding substantially to the performance and efficiency of production procedures across numerous markets. One considerable benefit is the capacity to produce complicated forms that would certainly be impossible or challenging to achieve through various other producing methods. This complexity permits greater layout versatility, making it possible for designers to enhance parts for performance and performance.

Additionally, Metal Casting can generate high-grade get rid of superb surface area coatings and dimensional accuracy, minimizing the requirement for comprehensive post-processing. Aluminum Foundry. The process is also very scalable, accommodating both huge and little manufacturing runs without considerable modifications in tooling or configuration

Metal Casting often result in less material waste compared to standard machining techniques, promoting more sustainable manufacturing techniques. In general, the adaptability and performance of Metal Casting make them a recommended selection in sectors such as automotive, aerospace, and building and construction, enhancing performance and lowering prices.

Innovations in Metal Casting Technologies

As advancements in modern technology remain to improve the manufacturing landscape, developments in Metal Casting are arising to enhance accuracy, sustainability, and effectiveness. Current advancements include the assimilation of computer-aided style (CAD) and computer-aided manufacturing (CAM) systems, which permit for complex designs and lowered manufacturing times. Additionally, 3D printing innovation has changed mold-making, allowing rapid prototyping and customization without the need for typical tooling.

The use of clever materials and innovative alloys is increasing the efficiency abilities of actors products, resulting in lighter and more powerful components. Automation and robotics are additionally playing a considerable function, improving processes and decreasing human error in production settings. These advancements not just boost the top quality of Metal Casting but likewise add to cost-effectiveness via decreased waste and much shorter lead times. As the market advances, these technical innovations guarantee to redefine the future of Metal Casting.

Lasting Practices in Metal Casting

Sustainable methods in Metal Casting are obtaining prominence as manufacturers look for to reduce their environmental influence while maintaining productivity. Secret strategies consist of the usage of recycled products, which considerably reduce resources consumption and energy usage. By integrating scrap steel into the casting process, companies can decrease their carbon footprint and promote resource effectiveness.

Additionally, developments in energy-efficient technologies, such as electrical heaters and improved insulation, are being embraced to enhance power usage during production. Moreover, suppliers are significantly applying water conservation techniques to reduce waste and warranty sustainable water management practices.

In addition, the fostering of ecologically friendly casting products, such as eco-friendly binders, is on the rise, changing standard compounds that may release dangerous discharges. Generally, the commitment to sustainability in Metal Casting not only addresses environmental issues however also boosts the market's competitiveness and long-lasting viability in a swiftly progressing market.

Situation Researches: Success Stories of Metal Castings

The influence of Metal Casting can be seen across different markets, highlighting their flexibility and efficiency. In the auto market, ingenious spreading strategies have led to lighter and more fuel-efficient vehicles, while aerospace growths have actually led to advanced elements that boost performance and safety and security. Additionally, the medical area has benefited from accuracy spreadings that improve device capability and patient results.

Automotive Market Innovations

Advancement in the automobile sector has actually been notably enhanced by advancements in Metal Casting methods, which have actually permitted makers to generate lighter, more resilient elements. A leading automotive company carried out high-pressure die casting to develop engine blocks that are not just lighter however additionally display remarkable thermal effectiveness. This change considerably boosted gas economy in their newest vehicle versions. An additional study highlights using sand spreading for producing intricate transmission parts, resulting in enhanced performance and integrity. In addition, the intro of 3D printing in Metal Casting procedures has actually made it possible for the manufacturing of intricate geometries, helping with design adaptability and lowering waste. Jointly, these technologies display how Metal Casting are improving the automotive landscape, driving innovations in performance and sustainability.

Aerospace Element Dope

Improvements in Metal index Casting have actually additionally made significant strides in the aerospace field, where the need for lightweight and high-strength elements is important. Business have efficiently used sophisticated casting techniques to produce components such as generator blades and structural structures. For example, a leading aerospace manufacturer implemented financial investment casting to create intricate forms that enhance efficiency while reducing weight. This method not only minimized manufacturing prices however also improved the resilience of the components. An additional remarkable case entailed the use of 3D printing combined with Metal Casting, making it possible for rapid prototyping and faster turn-around times for brand-new designs. These success tales highlight the transformative impact of Metal Casting technologies, facilitating innovation and efficiency in aerospace production.

Clinical Gadget Applications

Metal Casting have become a critical modern technology in the advancement of clinical tools, giving services that boost both capability and client safety. Instance researches illustrate the successful integration of Metal Casting in different applications. As an example, orthopedic implants made through precision casting strategies offer improved stamina and biocompatibility, substantially enhancing patient end results. In one more circumstances, personalized surgical tools are created utilizing Metal Casting, permitting tailored services that meet directory particular step-by-step requirements. Additionally, the usage of light-weight steel alloys in analysis tools has actually resulted in enhanced portability and simplicity of usage in professional setups. These success stories underscore the critical role of Metal Casting beforehand clinical technology, ensuring gadgets are not only effective yet likewise safe for client treatment.

Future Fads in Metal Casting Applications

The future of Metal Casting applications is poised for significant improvement via the assimilation of additive production and wise production innovations. These improvements guarantee to improve performance and accuracy in casting procedures while attending to the growing demand for lasting practices. As sectors advance, the adoption of cutting-edge techniques will likely redefine traditional spreading methods and add to a more ecologically accountable approach.

Additive Production Assimilation

As sectors look for ingenious services to enhance production effectiveness and lower waste, the integration of additive manufacturing into Metal Casting procedures becomes a transformative pattern. This synergy enables for the creation of complex geometries that conventional approaches struggle to achieve. By employing 3D printing techniques, makers can generate molds and cores with elaborate styles, considerably decreasing lead times and product consumption. Additionally, additive manufacturing promotes quick prototyping, making it possible for quicker versions and changes in style. This advancement not just simplifies production however likewise motivates customization, providing to particular customer requirements. As this integration proceeds to progress, it holds the potential to redefine Metal Casting applications, offering improved accuracy, decreased expenses, and a much more sustainable strategy to manufacturing in numerous sectors.

Smart Production Technologies

Welcoming wise manufacturing modern technologies notes a substantial shift in the future of Metal Casting applications. These improvements integrate automation, data analytics, and the Internet of Points (IoT), improving production efficiency and quality assurance. By utilizing sensing units and real-time surveillance, manufacturers can maximize processes, lower waste, and predict devices failures prior to they happen. In addition, clever modern technologies allow far better modification of spreadings, permitting a lot more complex styles and faster turn-around times. The adoption of artificial intelligence in quality control even more boosts flaw discovery, guaranteeing greater item criteria. As these modern technologies evolve, they will not just streamline operations yet also foster technology in Metal Casting, positioning business to fulfill the needs of a swiftly altering industrial landscape.

Sustainable Casting Practices

Although traditional Metal Casting approaches have actually long been integral to production, a growing focus on sustainability is reshaping practices within the sector. Modern shops are increasingly embracing green products and processes, such as making use of recycled steels, which considerably lowers the ecological impact. Furthermore, innovations in innovation make it possible for much more reliable energy usage, decreasing waste and emissions during manufacturing. The unification of additive production techniques additionally boosts sustainability by reducing material waste and allowing for complex styles that were previously unattainable. Additionally, industry stakeholders are prioritizing life cycle evaluations to evaluate the environmental effect of Metal Casting. As the need for greener options rises, lasting spreading methods are positioned to come to be a criterion in Metal Casting, cultivating an extra liable and cutting-edge manufacturing landscape.

Frequently Asked Questions

What Products Are Generally Made Use Of in Metal Casting?

Typical products used in Metal Casting include aluminum, iron, steel, bronze, and magnesium. Each product offers distinct buildings, making them ideal for numerous applications, from auto parts to detailed imaginative styles in manufacturing processes.

How Does Metal Casting Contrast to Machining Processes?

Metal Casting usually provides greater design flexibility and can generate intricate shapes much more efficiently than machining. Nonetheless, machining supplies greater precision and finer surface area finishes, making each procedure suitable for various click reference applications in manufacturing.

What Are the Common Costs Related To Metal Casting?

Regular costs related to Metal Casting vary based upon variables like product, quantity, and complexity. First configuration can be high, however big manufacturing runs substantially decrease per-unit prices, making it financially viable for different applications.

For how long Does the Metal Casting Process Take?

The Metal Casting process commonly takes anywhere from a few hours to a number of weeks, depending on elements such as the intricacy of the style, the material utilized, and the dimension of the cast item.

What Precaution Are Needed in Metal Casting Facilities?

Metal Casting centers call for precaution such as appropriate ventilation, safety gear, emergency devices, and normal training. Additionally, preserving devices and adhering to safety and security protocols guarantees a safer working environment for all workers entailed in the procedure.

Metal Casting entails several vital methods, including sand casting, investment casting, and pass away spreading, each customized to certain applications and products. Ultimately, the medical field utilizes specialized castings for surgical tools and implants, showcasing the convenience of Metal Casting throughout varied applications. As improvements in innovation proceed to reshape the production landscape, advancements in Metal Casting are emerging to boost precision, efficiency, and sustainability. As sectors look for cutting-edge solutions to boost production performance and minimize waste, the assimilation of additive manufacturing right into Metal Casting procedures arises as a transformative trend. Embracing smart production modern technologies notes a significant shift in the future of Metal Casting applications.